Descripción

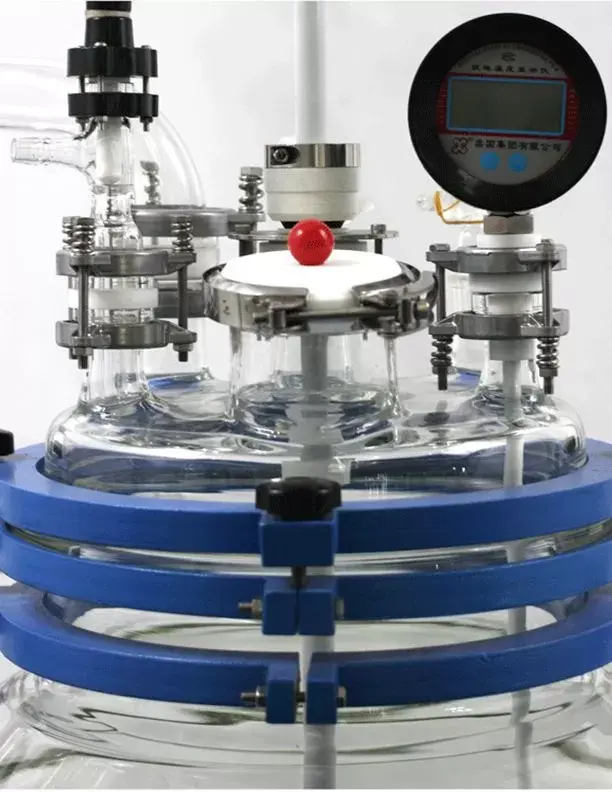

The 80-100L Explosion-Proof Jacketed Glass Reactor is a high-capacity reactor designed for safe and efficient processing of flammable or volatile substances in industrial and laboratory environments. Engineered with explosion-proof features, precise temperature control, and robust construction, this reactor is ideal for large-scale chemical synthesis, pharmaceutical manufacturing, and material research.

Quick Details

| Capacity | 80L-100L |

| Automatic Grade | Automatic |

| Type | Reaction Kettle |

| Core Components: | Engine, Motor |

| Glass Material: | High Borosilicate Glass 3.3 |

| Working Temperatur: | -100-250 |

| Heating Method: | Thermal Oil Heating |

| After Warranty Service: | Online support |

Product Attribute

| Product Modle | FPGR-80 | FPGR-100 |

| Volume(L) | 80 | 100 |

| Neck No.on Cover | 6 | 6 |

| External Diameter of Inner Vessel(mm) | 410 | 460 |

| External Diameter of Outer Vessel(mm) | 460 | 500 |

| Cover Diameter(mm) | 340 | 340 |

| Vessel Height(mm) | 950 | 950 |

| Motor Power(w) | 370 | 370 |

| Vacuum Degree(Mpa) | 0.098 | 0.098 |

| Rotation Speed(rpm) | 50-600 | 50-600 |

| Torque(Nm) | 5.89 | 5.89 |

| Power(V) | 220 | 220 |

| Diamension(mm) | 1000*700*2500 | 1000*700*2700 |

Key Features

Explosion-Proof Design

- Equipped with certified explosion-proof electrical components, including motors, controllers, and switches, to ensure safe operation in environments with hazardous substances.

- Advanced sealing technology prevents leaks, reducing the risk of contamination or accidents.

Premium Material Construction

- High-Borosilicate Glass: Offers superior resistance to chemical corrosion, thermal shock, and high-pressure conditions, ensuring durability and safety.

- Jacketed Design: Allows efficient heat exchange with precise temperature control in the range of -80°C to 200°C, suitable for both heating and cooling applications.

Large-Capacity Options

- Available in 80L and 100L capacities, catering to large-scale industrial applications and pilot plant operations.

- High-torque explosion-proof stirring motor ensures uniform mixing, even for viscous or heavy materials.

Advanced Explosion-Proof Control System

- Explosion-proof control panel supports precise management of reaction parameters such as temperature, stirring speed, and timing.

- Real-time monitoring and programmable settings enable automated processes for enhanced efficiency and reproducibility.

Customizable Design

- Modular design allows integration with auxiliary equipment such as reflux condensers, feeding systems, distillation heads, and collection vessels.

- Adaptable to various experimental and production requirements.

Enhanced Safety Features

- Includes over-temperature alarms, overload protection, and emergency stop functions to ensure operator and equipment safety.

Applications

The 80-100L Explosion-Proof Jacketed Glass Reactor is suitable for:

- Chemical Industry: Large-scale synthesis, catalytic reactions, and distillation of volatile compounds.

- Pharmaceutical Production: Safe formulation and production of active pharmaceutical ingredients (APIs).

- Petrochemical Research: Handling flammable and reactive substances in controlled environments.

- Material Science: High-volume crystallization, polymerization, and nanomaterial synthesis.

Advantages

- Maximum Safety: Explosion-proof design and advanced sealing technology provide peace of mind when working with hazardous materials.

- Precision and Control: Advanced temperature and stirring systems ensure consistent and accurate operation.

- Durable and Reliable: Built with high-quality materials to withstand challenging operational conditions.

- Scalable Solutions: Designed to meet the needs of industrial-scale projects with customizable configurations.

Why Choose Us?

The 80-100L Explosion-Proof Jacketed Glass Reactor combines advanced technology, safety, and efficiency, making it the preferred choice for industrial facilities and laboratories handling hazardous substances on a large scale.