Description

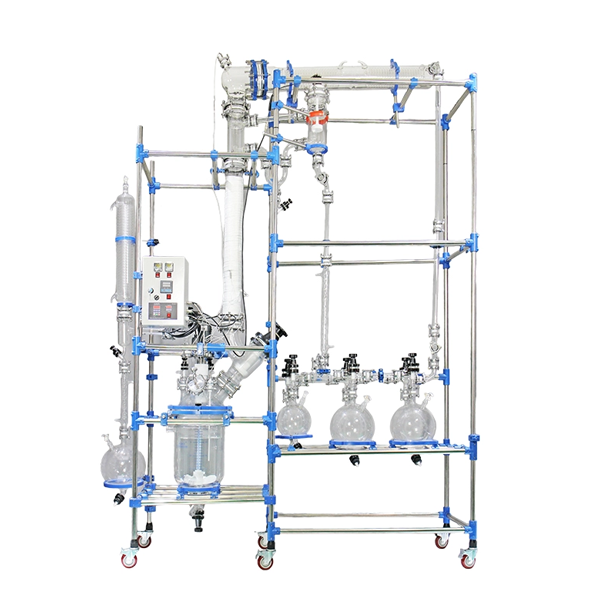

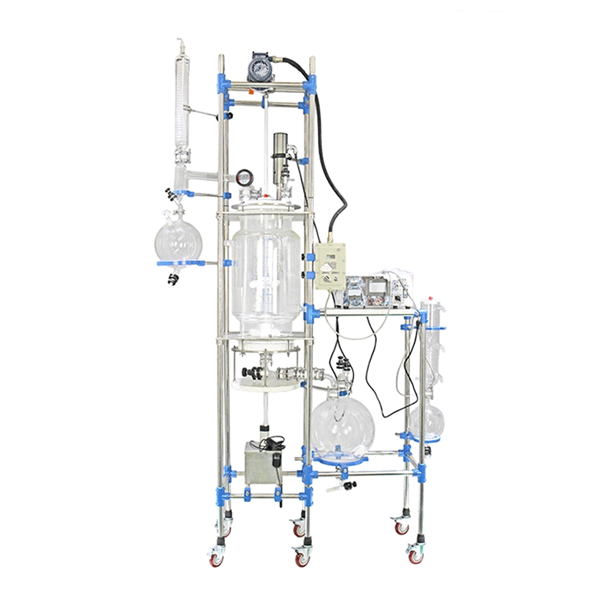

The Chemical Cylindrical Vacuum Glass Reactor is designed for chemical and industrial applications that require precise control under vacuum conditions. Built for laboratories and large-scale production environments, this reactor is ideal for distillation, solvent evaporation, chemical synthesis, and other processes that benefit from reduced pressure. The reactor’s cylindrical shape ensures uniform heat distribution and effective mixing, making it an essential tool for researchers, manufacturers, and chemical engineers.

Key Features of the Chemical Cylindrical Vacuum Glass Reactor:

- Vacuum Operation for Enhanced Reaction Efficiency: The vacuum design allows for efficient chemical reactions by lowering the boiling points of liquids. This leads to faster reaction times, improved yields, and lower energy consumption, making it ideal for applications like solvent evaporation and distillation.

- Durable Borosilicate Glass Construction: Made from high-quality borosilicate glass, the reactor offers exceptional chemical resistance, high thermal shock resistance, and transparency. This ensures both durability and easy observation of the reaction process, while also providing chemical inertness to prevent contamination.

- Cylindrical Design for Optimal Mixing: The reactor’s cylindrical shape ensures even heat distribution, improving the uniformity of temperature and mixing during reactions. This helps maintain consistent results and facilitates high-quality chemical processes.

- Precision Temperature and Pressure Control: Equipped with integrated controllers, the reactor allows precise regulation of both temperature and pressure, ensuring optimal conditions for sensitive reactions and reducing the risk of unwanted side reactions.

- Customizable for Specific Applications: Available in various sizes and configurations, this reactor can be customized to meet the needs of different chemical processes. Whether you need it for small-scale laboratory experiments or large-scale industrial applications, the Chemical Cylindrical Vacuum Glass Reactor can be tailored to your exact specifications.

- Safety and Security: The reactor features multiple safety mechanisms, such as pressure relief valves and securely sealed connections, to ensure safe operation under vacuum conditions. These features minimize the risk of accidents and ensure smooth, uninterrupted reactions.

Applications of the Chemical Cylindrical Vacuum Glass Reactor:

- Chemical Synthesis: Perfect for carrying out a variety of chemical synthesis reactions under controlled vacuum conditions, the reactor ensures enhanced efficiency and better reaction rates, leading to higher yields and more consistent products.

- Pharmaceutical Applications: Ideal for the pharmaceutical industry, the reactor facilitates API synthesis and other drug development processes. It helps to maintain consistent temperature and pressure, ensuring high-quality, reproducible results.

- Distillation and Solvent Evaporation: The vacuum feature of this reactor makes it ideal for distillation and solvent evaporation. By reducing the boiling point of solvents, it accelerates these processes and improves separation efficiency.

- Polymerization and Monomer Reactions: Used extensively in polymer chemistry, the reactor provides the controlled environment needed for successful polymerization reactions, leading to high-quality polymers with consistent properties.

- Food and Beverage Processing: In the food and beverage industry, this reactor is used for extracting essential oils, flavors, and bioactive compounds, providing a gentle and efficient process that preserves the integrity of sensitive ingredients.

- Environmental Applications: The Chemical Cylindrical Vacuum Glass Reactor can also be used in environmental remediation processes, including the treatment of waste and the breakdown of contaminants, thanks to its effective vacuum operation and reaction control.

Why Choose Our Chemical Cylindrical Vacuum Glass Reactor?

- Vacuum Technology for Fast and Efficient Reactions: The vacuum design allows for reduced boiling points, enhancing reaction efficiency and reducing energy consumption.

- Superior Durability and Clarity: Made from high-quality borosilicate glass, the reactor offers long-lasting durability and clarity for easy monitoring of the reaction process.

- Customizable to Meet Your Needs: Available in various sizes and configurations, the reactor can be tailored to meet your specific needs, whether for small laboratory use or large-scale industrial production.

- Precision Control for Consistent Results: The integrated temperature and pressure controllers ensure precise regulation of reaction conditions, guaranteeing optimal performance and consistent outcomes.

- Safety Features for Secure Operation: The reactor includes built-in safety features such as pressure relief valves, secure seals, and durable construction to ensure safe and reliable operation under vacuum conditions.

Optimize Your Chemical Processes with the Chemical Cylindrical Vacuum Glass Reactor

For advanced chemical processing, the Chemical Cylindrical Vacuum Glass Reactor provides the ideal solution. With its vacuum capabilities, borosilicate glass construction, and precision control features, this reactor offers efficient, reliable, and safe operation for a wide range of industrial, pharmaceutical, and research applications.