Description

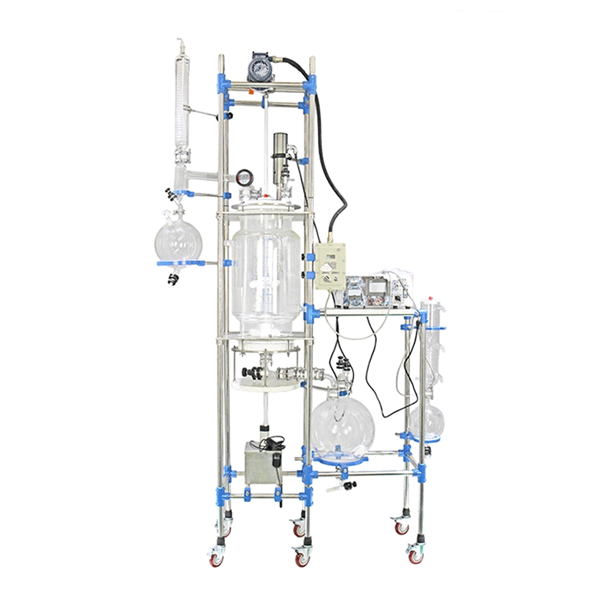

The Chemical Glass Reactor with Ultrasonic Wave System is designed to optimize chemical reactions and processing by integrating advanced ultrasonic technology with traditional glass reactor systems. This innovative reactor is ideal for a wide range of applications, including synthesis, emulsification, extraction, and chemical mixing, providing unparalleled efficiency and precision. By combining the power of ultrasonic waves with the durability and transparency of borosilicate glass, this reactor ensures high-performance results for both laboratory and industrial-scale processes.

Key Features of the Chemical Glass Reactor with Ultrasonic Wave System:

- Ultrasonic Wave Technology for Enhanced Reactions: The integration of ultrasonic waves creates powerful high-frequency sound waves that agitate molecules, leading to faster reaction times, improved mixing efficiency, and enhanced material processing. This feature is especially useful for emulsification, homogenization, and accelerating chemical reactions.

- High-Quality Borosilicate Glass Construction: Made from premium borosilicate glass, this reactor provides excellent chemical resistance, superior thermal shock resistance, and enhanced clarity for easy monitoring of the reaction. The glass material ensures durability, while also offering transparency to observe the reaction process.

- Precise Temperature and Pressure Control: Equipped with advanced temperature and pressure controllers, the reactor ensures that your chemical reactions are carried out under the most optimal conditions. This precise control helps maintain consistent results and prevents overheating or pressure build-up.

- Versatile Application for Various Industries: The Chemical Glass Reactor with Ultrasonic Wave System is versatile, making it ideal for a variety of industries such as pharmaceuticals, chemicals, food and beverage, cosmetics, and materials science. It is suitable for applications like mixing, chemical synthesis, extraction, and nanoparticle dispersion.

- Improved Efficiency and Yield: The ultrasonic waves break down the reactants more effectively, which leads to quicker and more efficient reactions, improved yield, and higher purity of the final product. The ultrasonic system also aids in the uniform distribution of heat and mass, which reduces energy consumption.

- Compact and Modular Design: Designed with ease of use in mind, this reactor system is compact and can be customized with various accessories and components to suit your specific requirements. The modular design allows for easy integration with existing laboratory equipment and other systems.

- Safe and Reliable Operation: The reactor includes built-in safety features such as pressure relief valves and sealed connections, ensuring smooth and safe operation even under challenging conditions. The ultrasonic system is also designed for minimal noise and vibration, offering a quieter and safer working environment.

Applications of the Chemical Glass Reactor with Ultrasonic Wave System:

- Pharmaceuticals and Drug Development: The ultrasonic waves accelerate chemical reactions, making this reactor ideal for the synthesis of active pharmaceutical ingredients (APIs), drug formulations, and other pharmaceutical applications that require precise temperature and pressure control.

- Cosmetics and Skincare: In the cosmetics industry, this reactor is used for the emulsification of ingredients, formulation of creams, lotions, and serums, and extraction of essential oils, ensuring high-quality products with improved texture and consistency.

- Food and Beverage Processing: The ultrasonic technology in this reactor improves the extraction of bioactive compounds, flavorings, and other natural substances from plants, providing enhanced flavor profiles and consistency in food and beverage products.

- Chemical Synthesis and Polymerization: Ultrasonic waves facilitate faster reactions and better mixing in chemical synthesis and polymerization processes, allowing for improved product yields and faster production cycles.

- Nanotechnology and Material Science: In material science, this reactor is used for the preparation of nanomaterials, dispersion of nanoparticles, and other processes that require fine control over reaction conditions and particle size.

- Environmental Remediation: The ultrasonic wave system enhances the efficiency of processes like wastewater treatment and environmental decontamination, breaking down pollutants and accelerating the chemical breakdown of harmful substances.

Why Choose Our Chemical Glass Reactor with Ultrasonic Wave System?

- Advanced Ultrasonic Technology: Ultrasonic waves provide enhanced reaction speed, better mixing, and improved yields, ensuring optimal results in various applications.

- Durable and Transparent Borosilicate Glass: The high-quality glass construction offers long-lasting durability, excellent chemical resistance, and allows easy observation of reactions.

- Precise Control for Consistent Results: With advanced temperature and pressure control systems, you can ensure that your reactions are conducted under the most optimal conditions for high-quality outputs.

- Versatile Applications Across Industries: Suitable for a wide range of industries, including pharmaceuticals, cosmetics, food and beverage, and environmental processing, this reactor offers a flexible solution for your chemical processing needs.

- Energy and Time Efficiency: The ultrasonic wave system reduces processing times and energy consumption, making the reactor a cost-effective option for large-scale production and laboratory experiments.

- Safety and Ease of Use: The reactor includes built-in safety features for secure operation and is easy to operate and maintain, ensuring a reliable working environment.

Optimize Your Chemical Processes with the Chemical Glass Reactor with Ultrasonic Wave System

For enhanced efficiency, precision, and productivity in chemical processing, the Chemical Glass Reactor with Ultrasonic Wave System offers a cutting-edge solution. Whether you’re in pharmaceutical research, cosmetic formulation, or material science, this reactor system provides the ideal conditions for rapid and efficient reactions with high-quality results.