Solution Customization

Solution customization is a critical phase in the glass reactor system integration process, ensuring that the proposed solution aligns with the customer’s specific requirements, operational goals, and industry standards. This step involves designing a tailored approach that maximizes efficiency, reliability, and compliance.

-

Technical Feasibility Evaluation

Our engineering team conducts a comprehensive feasibility analysis based on the initial requirements gathered during the requirement docking phase. We assess factors such as reactor volume, material compatibility (borosilicate glass, stainless steel), temperature and pressure tolerance, automation level, and integration with existing lab equipment. If any challenges arise, alternative solutions are proposed to optimize performance and cost-effectiveness. -

Customization of Product Specifications

Depending on the customer’s needs, we tailor glass reactor systems, rotary evaporators, and laboratory reaction equipment by adjusting key specifications. Customization may include:-

Volume customization (e.g., 5L, 20L, 50L, or industrial-scale reactors)

-

Jacketed or single-layer reactors for temperature control

-

Automation options such as PLC control systems

-

Explosion-proof designs for handling hazardous chemicals

-

Integration with auxiliary equipment like chillers, vacuum pumps, and circulation systems

-

-

Material Selection and Compliance

Selecting the right materials is essential for chemical resistance, durability, and safety. We ensure that all components meet international safety and quality standards, such as CE, ISO, and GMP compliance. If the customer has specific industry-related regulations, we modify the design accordingly. -

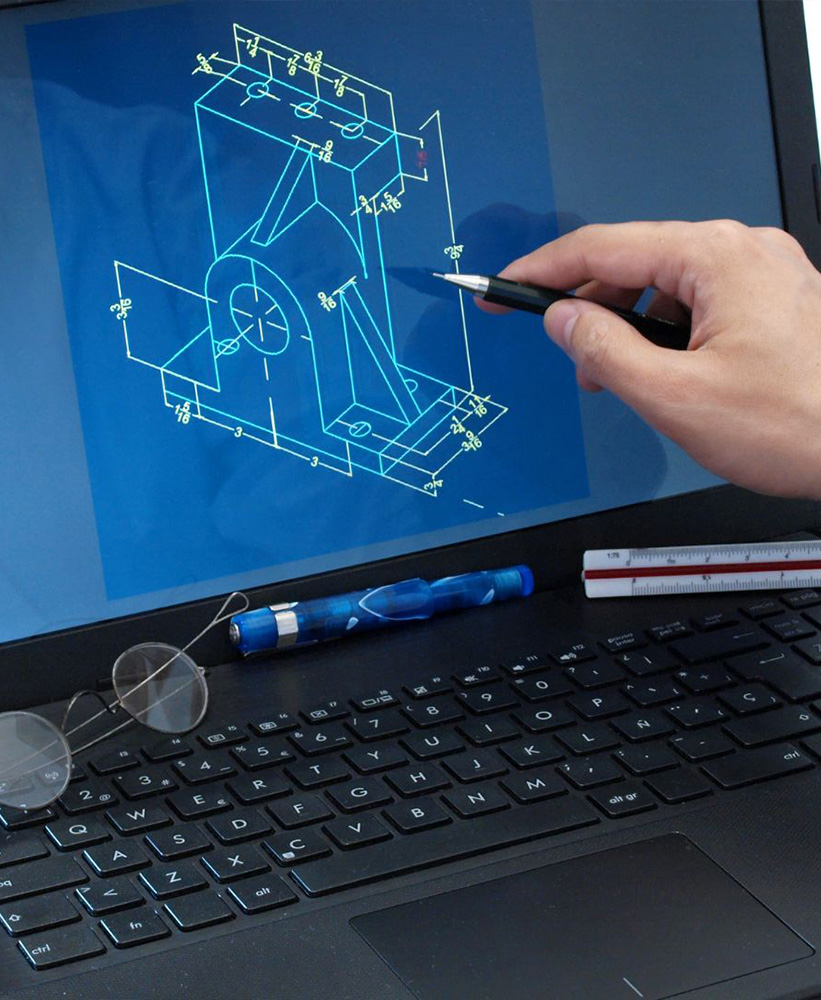

Prototype Development and Testing

Before mass production, we provide 3D models, CAD drawings, or prototypes for customer approval. Performance tests, including vacuum sealing, thermal stability, and mixing efficiency, are conducted to validate the customized solution. Any necessary modifications are made based on test results and customer feedback. -

Final Proposal and Agreement

Once the customized solution meets all requirements, we present a detailed proposal outlining the final specifications, production timeline, quality assurance processes, and pricing structure. Customers review and confirm the proposal before moving on to the production and delivery phase.

By customizing laboratory glass reactor systems and process equipment, we ensure that our solutions meet the highest industry standards while addressing the unique operational needs of each client. This approach guarantees high performance, efficiency, and long-term reliability in laboratory and industrial applications.