A jacketed filter reactor is a special container for reactions. It helps with mixing and filtering under controlled settings. Think of it as a tool that controls temperature and filters at the same time. The jacket around the container helps heat or cool it easily. These reactors are very important in making medicines, chemicals, and food. They help keep products safe and high-quality. Using this reactor gives accurate results and makes work easier.

Design and Parts of a Jacketed Filter Reactor

The Jacket: Purpose and Use

The jacket in these reactors helps control the temperature. It wraps around the reactor and lets hot or cold fluids flow. This keeps the temperature steady, which is important for reactions. For example, it cools down heat-making reactions and warms up heat-needing ones.

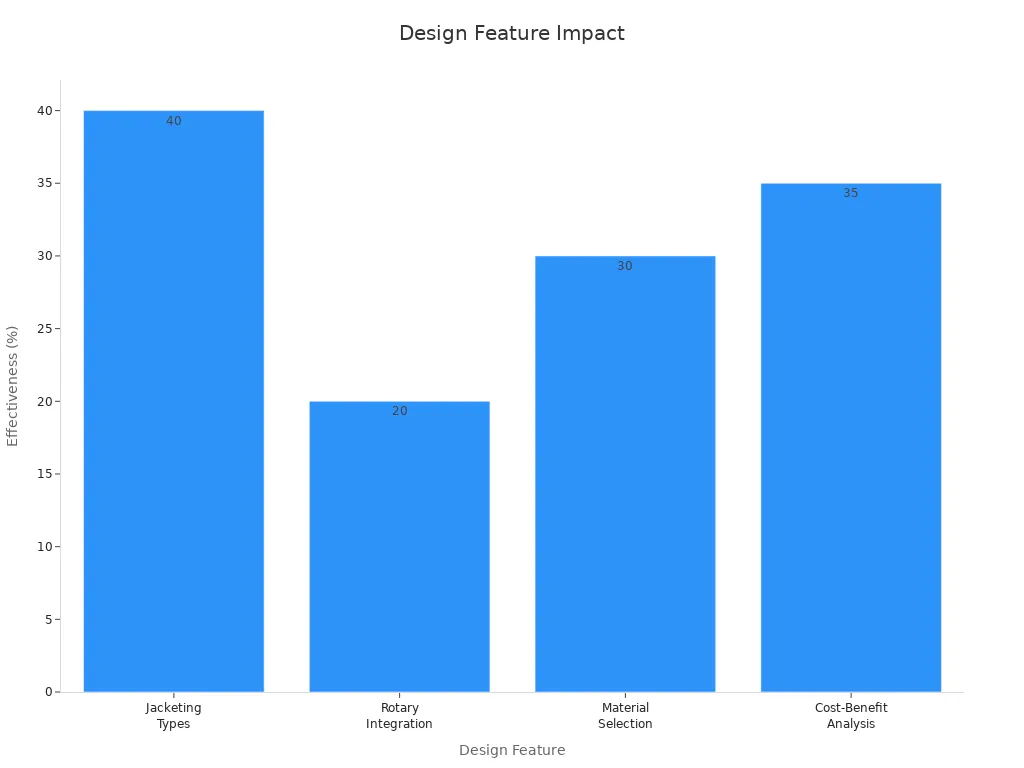

Some reactors use special jackets like half-pipe coils or dimple jackets. These designs make heating or cooling faster by up to 40%. This saves time and lowers costs. Modern reactors can also connect to systems that let you easily check and change temperatures.

Tip: Always check the jacket’s pressure and temperature limits for safety.

Reactor Vessel: Material and Build

The reactor vessel is the main part of the reactor. It is usually made of stainless steel or glass, depending on its use. Stainless steel lasts long and cuts maintenance costs by up to 30%. Glass vessels let you see the reaction as it happens.

Safety rules like the ASME Code make sure these vessels are safe and strong. For instance, glass reactors often follow ASME Section VIII for pressure safety. These rules also cover use in risky areas, like places with flammable gases or earthquakes.

| Material Type | Benefits |

|---|---|

| High-Grade Stainless Steel | Strong, affordable, and works well under high pressure. |

| Glass | Clear, great for watching reactions, and resists rust. |

Filtration System: How It Works

The filtration system separates solids from liquids during reactions. It has a filter plate or mesh at the bottom of the vessel. After the reaction, the mixture goes through the filter. Solids stay behind, and liquids flow out.

This system works well to separate materials and reduce waste. Advanced designs can recycle or remove unwanted materials. Filtration systems also have flow lines and energy-saving features to work better.

Note: Clean the filter system often to avoid clogs and keep it working well.

Additional Features: Agitators, Valves, and Ports

Agitators, valves, and ports are important parts of jacketed filter reactors. They help the reactor work better and handle many tasks.

Agitators: Helping with Mixing

Agitators mix everything inside the reactor evenly. This stops uneven reactions and helps materials combine properly. You can change the speed or type of mixing based on what you need. For example, drug companies use agitators to mix medicine ingredients evenly. Some designs, like OptiMix, make mixing faster by 25%, saving time and energy.

Tip: Pick agitators with adjustable speeds for more control.

Valves: Controlling Flow and Pressure

Valves manage how materials move in and out of the reactor. They also keep the pressure inside safe. Good valves stop leaks and make the reactor safer to use. Newer valves can handle higher pressure, up to 130 psig. This means fewer repairs and lower maintenance costs.

Ports: Easy Access and Use

Ports let you add or remove materials, check reactions, or connect tools. Bigger ports, like manways, make cleaning and fixing easier. You can also add more nozzles for tools like sensors or samplers. These features make the reactor more useful and easier to handle.

- Main Benefits of New Designs:

- Bigger manways for easy cleaning

- Fewer gaskets to prevent leaks

- Extra nozzles for more uses

Agitators, valves, and ports make these reactors flexible for tough jobs. Choosing reactors with these features boosts efficiency, saves time, and gives better results.

How Does a Jacketed Filter Reactor Work?

Keeping the Temperature Steady with the Jacket

The jacket in this reactor helps control the temperature. It wraps around the vessel and lets fluids flow through. These fluids heat or cool the reactor as needed. This keeps the reaction at the right temperature. Systems can track the temperature and let you adjust it quickly. The jacket stops sudden temperature changes, which is important for heat-sensitive reactions.

- Benefits of the jacket include:

- Keeps the temperature steady with fluid flow.

- Stops overheating or overcooling during reactions.

- Makes sensitive processes safer and more efficient.

With a jacketed reactor, you get stable and reliable temperature control.

How the Filtration System Works

The filter system separates solids from liquids during or after reactions. A filter plate or mesh at the bottom catches solids. Liquids pass through and leave the reactor clean. This process removes unwanted materials from your products.

New designs make filtration faster and reduce waste. Some systems save energy by improving liquid flow through the filter. Cleaning the filter often is important to avoid clogs and keep it working well.

Tip: Check the filter regularly to prevent problems during reactions.

Working with Other Systems

Jacketed reactors can connect to other systems to work better. You can link them to temperature controllers, sensors, or automation tools. These connections help you monitor and adjust reactions from a distance.

For example, linking the reactor to a data system lets you track progress live. This is very helpful in industries like medicine, where accuracy matters. By connecting to other systems, the reactor becomes more useful for complex tasks.

Note: Make sure the reactor works well with other systems to avoid issues.

Applications of Jacketed Filter Reactors

Pharmaceutical Industry: Making and Cleaning Medicines

Jacketed filter reactors are very useful in making medicines. They keep the temperature steady during drug-making, which protects the ingredients. These reactors also clean by removing unwanted solids in one step. This saves time and reduces the need for extra machines.

Big companies like GSK use these reactors to make drugs faster. They find problems early and save about 200 days each year. This helps new medicines reach people quicker. The reactors also catch issues, like clumping, that older methods might miss.

Chemical Industry: Controlling Reactions and Cleaning Products

In the chemical field, these reactors help control reactions and clean products. The jacket keeps the heat or cold steady, which improves reaction speed. This makes better products and reduces waste. The built-in filter removes impurities during production, making the process smoother.

Studies show these reactors reduce the need for extra testing tools. They also handle quick changes well, as shown in the table below. This makes them great for tricky chemical reactions.

| Tuning Type | Kc (%/°C) | T*i (min) | T*d (min) | Extra Info |

|---|---|---|---|---|

| Moderate Response | -0.61 | 2.2 | N/A | N/A |

| PID | -0.77 | 2.6 | 0.34 | N/A |

| PID w/ Filter | -0.72 | 2.6 | 0.34 | a = 1.1 |

| Aggressive Response | -3.1 | 2.2 | N/A | N/A |

| PID | -5.0 | 2.6 | 0.34 | N/A |

| PID w/ Filter | -3.6 | 2.6 | 0.34 | a = 0.5 |

Food and Beverage Industry: Making and Cleaning Foods

These reactors are also helpful in food and drink production. They keep the right temperature for things like fermentation and pasteurization. The filter removes solids, like pulp, to make cleaner products.

They work well for batch processes where quality matters. For example, they handle sensitive ingredients without ruining taste or texture. Combining heat control and filtering in one machine saves money for food makers.

Environmental Testing: Preparing and Checking Samples

Jacketed filter reactors are important for environmental testing. They help prepare and check samples for harmful substances like toxins or pollutants. The reactor keeps the temperature steady, which is needed for accurate results. This is useful for processes like separating chemicals or extracting materials.

For example, when testing water for pollutants, the filter separates solids from liquids easily. The built-in filter removes unwanted particles without needing extra tools. This saves time and reduces waste. Some advanced designs even recycle filtered materials, making the process greener. With one reactor, you can heat, cool, and filter, saving effort and improving results.

Tip: Clean the filter often to keep results accurate and avoid contamination.

Research and Development: Handling Complex Reactions

In research, jacketed filter reactors are great for multi-step reactions. They help with tricky chemical processes that need exact temperature control and filtering. For example, when creating new drugs or materials, the reactor ensures each step is done perfectly.

The filter system makes it easy to remove byproducts or impurities during reactions. This means you don’t need extra filtering tools, saving time and money. These reactors can also connect to monitoring systems, letting you watch progress live. This is very helpful when testing new ideas or increasing production.

By combining heating, cooling, filtering, and monitoring, these reactors make research faster and more reliable. They also help you get consistent results, which is key for new discoveries.

Note: Pick a reactor with settings you can adjust to fit your experiments.

Advantages of Using a Jacketed Filter Reactor

Precise Temperature Control

A jacketed filter reactor helps keep the temperature just right. The jacket around it lets you heat or cool easily. This ensures reactions happen at the best temperature, which is very important. For example, in making medicines, the right temperature stops ingredients from breaking down.

Modern systems let you watch and change the temperature instantly. This lowers mistakes and makes results more reliable. Whether you need steady heat or quick cooling, the jacket design helps.

Tip: Check temperature settings before starting to avoid sudden changes.

Enhanced Process Efficiency

A jacketed reactor makes your work faster and easier. It combines temperature control and filtering, so you need fewer tools. This saves time and cuts costs. For example, the filter separates solids and liquids during reactions, skipping extra steps.

The reactor also heats and cools faster. This means you finish tasks quicker without losing quality. By doing many jobs in one system, you can focus on better results.

Note: Keep the jacket and filter clean for long-lasting performance.

Versatility Across Applications

A jacketed filter reactor works for many different tasks. It can heat, cool, and filter, making it useful in medicine, chemicals, and food. You can use it for making drugs, chemical reactions, or food processing like pasteurization.

The reactor’s design lets you change it for special needs. For example, you can add ports for samples or sensors to check progress. This flexibility makes it great for both big factories and research labs.

Tip: Pick a reactor with adjustable parts to fit your industry’s needs.

Better Product Quality and Safety

A jacketed filter reactor helps make products better and safer. It keeps the temperature just right for reactions. This stops unwanted reactions that could ruin the product. For example, in making medicines, the right temperature protects ingredients. This keeps the medicine effective and safe to use.

The built-in filter also improves product quality. It removes dirt and unwanted solids during the process. This gives cleaner and purer results without needing extra tools. You can trust this system to give the same good results every time. This is very important in industries like food and chemicals.

Safety is another big benefit. The reactor’s design keeps conditions stable to avoid risks. Strong jackets and secure valves stop accidents from sudden changes in pressure or heat. Modern systems let you watch and change settings as needed. This lowers mistakes and makes the workplace safer.

Tip: Clean the jacket and filter often to keep them working well and lasting longer.

With smart temperature control, good filtering, and strong safety features, a jacketed filter reactor helps you make high-quality products while keeping the process safe and smooth.

A jacketed filter reactor is a useful machine. It controls temperature and filters in one system. It is important in making medicines, chemicals, and food. It ensures accurate reactions and good-quality products. It works well for tough tasks in factories and labs.

Key Takeaway: A jacketed filter reactor saves time, cuts waste, and boosts safety.

To improve your work, talk to an expert. The right reactor can make your processes better and give great results.